As the world builds more and more electric cars and trucks—and electrifies other modes of transit—a race is underway to build the ideal, mean-and-green motor. The goal is a traction motor that’s at least as powerful, reliable, and lightweight as today’s industry standard rare-earth permanent magnet synchronous motor. However, rare-earth elements like neodymium and dysprosium, which are required for the most powerful magnets for the latter, also represent a major choke point. Their mining and processing comes at an environmental cost, and China holds a near-monopoly stake in them. Which is why the race to build an EV motor without rare-earths is so important. These projects don’t get as much attention as the race for better batteries and ever-more gargantuan battery factories, but they will be no less vital to the future of electrified transportation.

The motor R&D projects take a variety of forms, including longstanding work to improve induction motors and various exotic types of synchronous motors, as well as efforts to build powerful synchronous motors with permanent magnets that don’t use rare earths.

“I am a believer that this type of material is a game changer.” Ayman El-Refaie, Marquette University

Now a sleeper option, synchronous reluctance motors, is getting a surge of interest, thanks to materials-science breakthroughs at GE Aerospace. GE is one of a couple of companies developing materials with a remarkable property: when exposed to a strong magnetic field, different regions of the material become magnetized at radically different levels of intensity—either not magnetized at all or very highly magnetized. In a stunning paper last year, GE researchers reported that they had used such a material, called a dual-phase magnetic material, to produce a rare-earth-free rotor for a synchronous reluctance motor that had impressive characteristics.

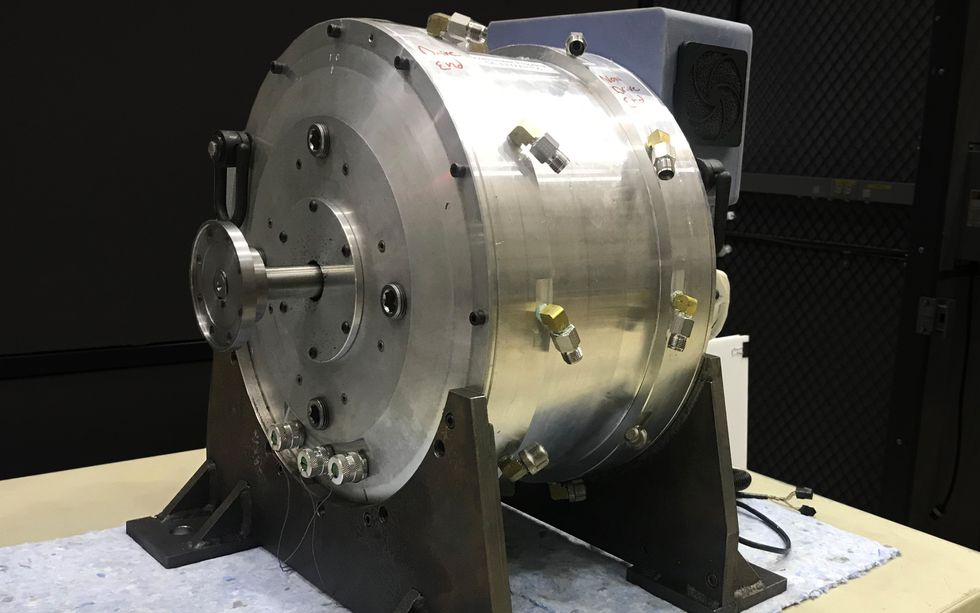

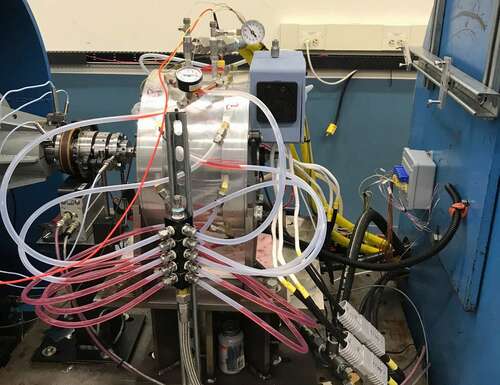

The 23-kilowatt experimental GE motor was tested on a dynamometer using a torque meter—the gray, cylindrical item with the fins at left. The translucent tubes contain red-colored oil circulated to cool the motor.GE Aerospace Research

“I am a believer that this type of material is a game changer,” says Ayman El-Refaie, an IEEE Fellow and professor of electrical and computer engineering at Marquette University in Milwaukee, Wisc. El-Refaie originated the GE program in dual-phase materials in 2005.

GE’s breakthrough material

In tests, the GE motor handily outperformed synchronous reluctance motors that were more or less identical except for having rotors fabricated with conventional magnetic materials. For example, in one trial, the motor with the dual-phase rotor had power output of 23 kilowatts at 14,000 rpm; the comparable conventional-rotor machine could manage only 3.7 kW. That dual-phase-equipped motor had a respectable mass power density of 1.4 kW per kilogram. (It fell short of the predicted value of 1.87 kW/kg because the prediction had been based on attributes of lab-scale or simulated parts rather than production ones.) Electric vehicles on the market today typically have motors with power densities between 1.1 and 3.0 kW/kg. The peak efficiency of the GE motor was 94 percent, on a par with the best motors used today in commercial EVs.

To understand the promise of dual-phase materials, start with some basics about synchronous reluctance motors. As with other motors, they have a stator and a rotor. A rotating magnetic field is created in the stator. This spinning field magnetizes and engages the rotor, which is usually made of a ferromagnetic alloy called electric steel. The rotor then spins because of a phenomenon called magnetic reluctance, which is the property that causes a ferromagnetic material to align itself with the lines of flux of a magnetic field. As the stator field rotates, the magnetized rotor continually tries to align itself with that rotating field, producing torque.

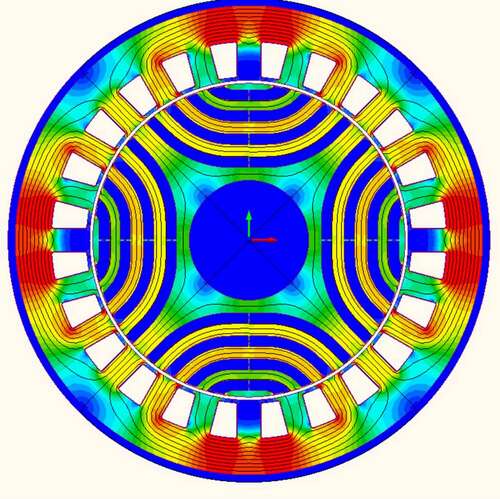

A four-pole rotor in a synchronous reluctance motor has areas that are very highly magnetized—shown in red—and others that are not magnetized (blue). This image shows the magnetization when the stator and rotor are aligned.Oak Ridge National Laboratory

One weakness of such a machine, however, involves the rotor. The magnetic interaction between the rotor and stator, which makes the rotor spin, is concentrated at evenly spaced positions, called poles, on the rotor and stator. The magnetic field lines from a pole on the rotor must be strongly linked to a corresponding pole on the stator. However, these field lines from the rotor poles have a tendency to interfere with each other, which reduces the lines, or flux, available to connect to the corresponding stator poles. “That will lower the overall torque that you can produce with the motor because the torque is primarily due to that flux linkage between the motor poles in the rotor and the stator,” says Frank Johnson, another veteran of the GE research team on dual-phase materials, and currently chief technical officer of Niron Magnetics in Minneapolis.

So to magnetically isolate the poles from each other, one option would be to minimize structures, called bridges and posts, around the poles of the rotor. With less magnetic material, these structures would produce less flux and therefore less interference. That’s actually not a good option, though, because minimizing those structures would leave those areas narrow and therefore mechanically weak. That weakness would greatly limit the speed at which the rotor could spin, which would in turn limit the motor’s power.

But with a dual-phase material, it is possible to make the bridges and posts non-magnetizable (the technical term is “non-permeable”), and yet wide and strong. That’s what GE did with its experimental motor.

No company is yet offering dual-phase magnetic materials suitable for the rotors of high-power traction motors. No one outside of GE Aerospace knows whether, or when, the company might license or manufacture its material. (GE Aerospace declined to make a researcher available to be interviewed for this article.) A survey article published in December in the Journal of Magnetism and Magnetic Materials concluded that GE’s material, which is produced in a process called high-temperature nitriding, “is the most developed method for producing dual-phase magnetic steel. Due to the high manufacturability of production, the final cost of the product is competitive compared to traditional electrical steel.”

Besides GE, the only other company known to be working on dual-phase magnetic materials is Proterial (formerly Hitachi Metals, which has been developing dual-phase magnetic materials since the 1990s). University research programs investigating similar technologies include ones at Ufa University of Science and Technology in Russia, Yeungnam University in Republic of Korea, Harbin Institute of Technology in China, and the University of Sheffield in the U.K.

El-Refaie, at Marquette, says that GE’s dual-phase material could be improved with further development. For example, the material’s maximum saturation flux density, a measure of how strongly magnetized the material can become, is 1.5 teslas—well below the 2 T limit of ordinary electric steel.

But technical advances are probably not the highest hurdle to commercialization, he adds. “Whether someone can bring it to the finish line, and establish a supply-chain for it, it’s not clear how this is going to happen,” says El-Refaie. “It’s not only about GE. They have to work with vendors if they want to make it available for the broader technical market.”

“A significant barrier will be finding a steel producer willing and able to produce the rolled metal sheet used to make the dual-phase rotor” material, adds Johnson. “The alloy that we developed has very low cost elements, which paradoxically makes it a difficult business case to justify except at very large manufacturing volumes requiring large amounts of capital equipment.”

But if the material does go into mass-scale production, the benefits would go well beyond synchronous reluctance motors. Projects at Marquette University, Yeungnam University, and Ufa University of Science and Technology have demonstrated advantages of dual-phase materials in permanent magnet synchronous motors and electrical generators.

“It’s not only IPM (interior permanent magnet motor) machines that can benefit,” says El-Refaie. “It can have advantages in other types of machines as well, for different reasons.”