Over the past decade, one of the biggest stories in semiconductors has been a surprise eclipsing of traditional silicon—in the field of power electronics, where silicon carbide (SiC) and gallium nitride (GaN) have raced past silicon to capture multibilllion-dollar segments of the market. And as major applications fell to these upstarts, with their superior attributes, a question naturally arose. What would be the next new power semiconductor—the one whose superior capabilities would grab major market share from SiC and GaN?

Attention has focused on three candidates: gallium oxide, diamond, and aluminum nitride (AlN). All of them have remarkable attributes, as well as fundamental weaknesses that have so far precluded commercial success. Now, however, AlN’s prospects have improved enormously thanks to several recent breakthroughs, including a technological advance at Nagoya University reported at the most recent IEEE International Electron Devices Meeting, held this past December in San Francisco.

How aluminum nitride edges up to (and ahead of?) SiC and GaN

The IEDM paper describes the fabrication of a diode based on alloys of aluminum nitride capable of withstanding an electric field of 7.3 megavolts per centimeter—about twice as high as what’s possible with silicon carbide or gallium nitride. Notably, the device also had very low resistance when conducting current. “This is a spectacular result,” says IEEE Senior Member W. Alan Doolittle, a professor of electrical and computer engineering at Georgia Tech. “Particularly the on-resistance of this thing, which is ridiculously good.” The Nagoya paper has seven coauthors, including IEEE Member Hiroshi Amano, who won a Nobel Prize in 2014 for his role in inventing the blue LED.

“This is a new concept in semiconductor devices.” —Debdeep Jena, Cornell

Aluminum nitride has long tantalized semiconductor researchers. One of the most important characteristics of a power semiconductor is its band gap. It’s the energy, in electron volts, needed for an electron in the semiconductor lattice to jump from the valence band to the conduction band, where it is free to move around in the lattice and conduct electricity. In a semiconductor with a wide bandgap, such as gallium nitride (GaN) or silicon carbide (SiC), the bonds between atoms are strong. So the material is able to withstand very intense electric fields before the bonds break and the transistor is destroyed. But they both pale in comparison with AlN. The bandgap of AlN is 6.20 electron volts; for GaN it’s 3.40 and for the most common type of SiC, 3.26.

One longstanding problem with AlN is in doping, which is the insertion of impurity elements that give a semiconductor an excess of charges, thereby enabling it to carry current. Strategies for chemically doping AlN have only begun emerging in recent years, are not fully developed, and their effectiveness is a somewhat contentious subject among researchers. In doping, the excess charges can be electrons, in which case the semiconductor is referred to as “n-type,” or they can be electron deficiencies called holes, in which case it’s “p-type.” Nearly all commercially successful devices are made up of such doped semiconductors, sandwiched together.

But impurity doping, it turns out, is not the only way to dope a semiconductor. Some semiconductors based on a compound containing elements from group III (a.k.a. the scandium group) and group V (vanadium group) in the periodic table—for example the compound gallium nitride—have an unusual and remarkable property. At the boundary where two such semiconductors meet, they can spontaneously generate a two-dimensional pool of extremely mobile charge carriers, called a 2-dimensional electron gas, even without chemical doping. It arises from an internal electric field in the crystal, which comes from a couple of attributes. For one, crystals of these III-V semiconductors are unusually polar: Within the unit cells of the crystal, the clouds of electrons and positively-charged nuclei are offset from each other enough to give every cell distinct negative and positive regions (a dipole). In addition, it’s possible to generate charges in the crystal lattice of these semiconductors simply by straining that lattice, a phenomenon called piezoelectricity.

The story behind the big advance

In the early 2000s, researchers at the University of California, Santa Barbara exploited these characteristics to develop a technique they called distributed polarization doping, which allowed them to get n-type doping of bulk (three-dimensional) gallium-nitride without impurity dopants. The group included IEEE Fellow Umesh Mishra (now dean of engineering at UCSB) and his graduate students Debdeep Jena and Huili (Grace) Xing, both now at Cornell University. Jena and Xing, both IEEE Fellows, later demonstrated p-type distributed polarization doping, in 2010, and then dopant-free 2-dimensional hole gases, in 2018, at Cornell.

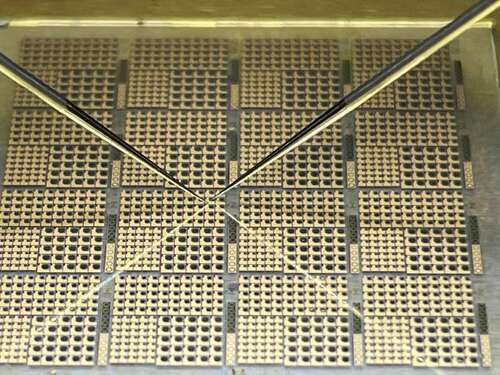

State-of-the-art aluminum nitride diodes are tested at Nagoya University.Nagoya University

State-of-the-art aluminum nitride diodes are tested at Nagoya University.Nagoya University

The Nagoya group built on those prior achievements by implementing the technique of dopant-free distributed polarization doping in aluminum nitride—or, more precisely, an alloy of aluminum-gallium-nitride (AlGaN) consisting of a mixture of AlN and GaN. Like any diode, their device has a p-doped region mated to an n-doped one, with a boundary, called a junction, in between. For both regions, the doping was accomplished with distributed polarization doping. They achieved the different polarizations, n-type and p-type, by establishing a gradient, in each of the doped regions, in the percentage of AlN vs. GaN in the alloy. Whether the doping is n-type or p-type depends simply on the direction of the gradient.

“Instead of having a uniform composition of AlGaN, the aluminum composition is changing spatially in a linear fashion,” says Jena. The p-doped layer starts off with pure gallium nitride on the side adjacent to the anode contact. Moving towards the junction with the n-doped layer, the percentage of aluminum nitride in the AlGaN alloy increases, until it reaches 95 percent AlN right at the junction. Continuing in the same direction, moving through the n-doped region, the percentage of AlN falls off with distance from the junction, starting at 95 percent and bottoming out at 70 percent AlN where that layer makes contact with the pure AlN substrate.

The ultimate goal is a commercially available aluminum nitride power transistor that is greatly superior to the existing options, and the Nagoya work has left little doubt that’s eventually going to happen.

“This is a new concept in semiconductor devices,” says Jena, of the Nagoya device. The next step, he adds, is fabricating a diode that has a layer of pure AlN at the junction, rather than 95 percent AlN. A layer of AlN just two microns thick would suffice to block 3 kilovolts, according to his calculations. “This is exactly where this will go in the very near future,” he says.

At Georgia Tech, Doolittle agrees that there is still room for enormous improvement by incorporating higher levels of pure AlN in future devices. For example, the breakdown electric field of the Nagoya diode, 7.3 MV/cm, is impressive, but the theoretical maximum for an AlN device is about 15. Thermal conductivity, too, would be greatly improved with more AlN. The ability to conduct heat is vitally important for a power device, and the thermal conductivity of the AlGaN alloy is mediocre—below 50 watts per meter-kelvin. Pure aluminum nitride, on the other hand, is very respectable at 320, in between GaN, at 250, and SiC, at 490.

The ultimate goal is a commercially available AlN power transistor that is greatly superior to the existing options, and the Nagoya work has left little doubt that’s eventually going to happen, according to both Jena and Doolittle. “It’s just engineering at this point,” says Doolittle. They both note that the Nagoya diode is a vertical device, which is the preferred orientation for a power semiconductor. In a vertical device, the current flows upward from the substrate directly to contacts on the top of the device—a configuration that allows maximum current flow.

At least half a dozen AlN-based transistors have been demonstrated in recent years, but none of these were vertical devices and none had characteristics competitive with commercially available GaN or SiC transistors. They, too, relied on AlGaN in key components of the device.

In an e-mail to IEEE Spectrum, IEEE Member Takeru Kumabe, a coauthor of the Nagoya paper, wrote, “we believe it is possible to demonstrate commercially competitive [power transistors] utilizing distributed polarization doping technology…. AlN-based vertical heterojunction bipolar transistors, which consist of two p–n junctions and exhibit good power and area efficiencies, are our targeted device, our dream, to be realized.”

Kumabe added that to realize that dream the team would focus on getting a deeper understanding of charge mobility, “carrier lifetime, critical electric field, and deep-level defects. Crystal-growth and device-fabrication technologies that produce high-quality device layers and introduce less damage during processing should also be developed.”

“We want to resolve these points within 3-5 years and commercialize AlN-based power devices in the 2030s,” he said.

From Your Site Articles

Related Articles Around the Web