In a nutshell: HZO specializes in thin film coatings for electronic devices. At CES 2024, the North Carolina-based company demonstrated the effectiveness of its coating process by submerging a Raspberry Pi board. Remarkably, the board continued working just fine and no one got electrocuted.

HZO offers innovative coating services using parylene, applied as a film at the “molecular level” through a vacuum deposition process. Parylene, thinner than other coating materials, is capable of uniformly and reliably covering electronic devices, including bare circuit boards. The company showed the parylene coating protection at work during CES 2024, suggesting that hardware companies could turn Raspberry Pi 4 boards into proper waterproof computer projects.

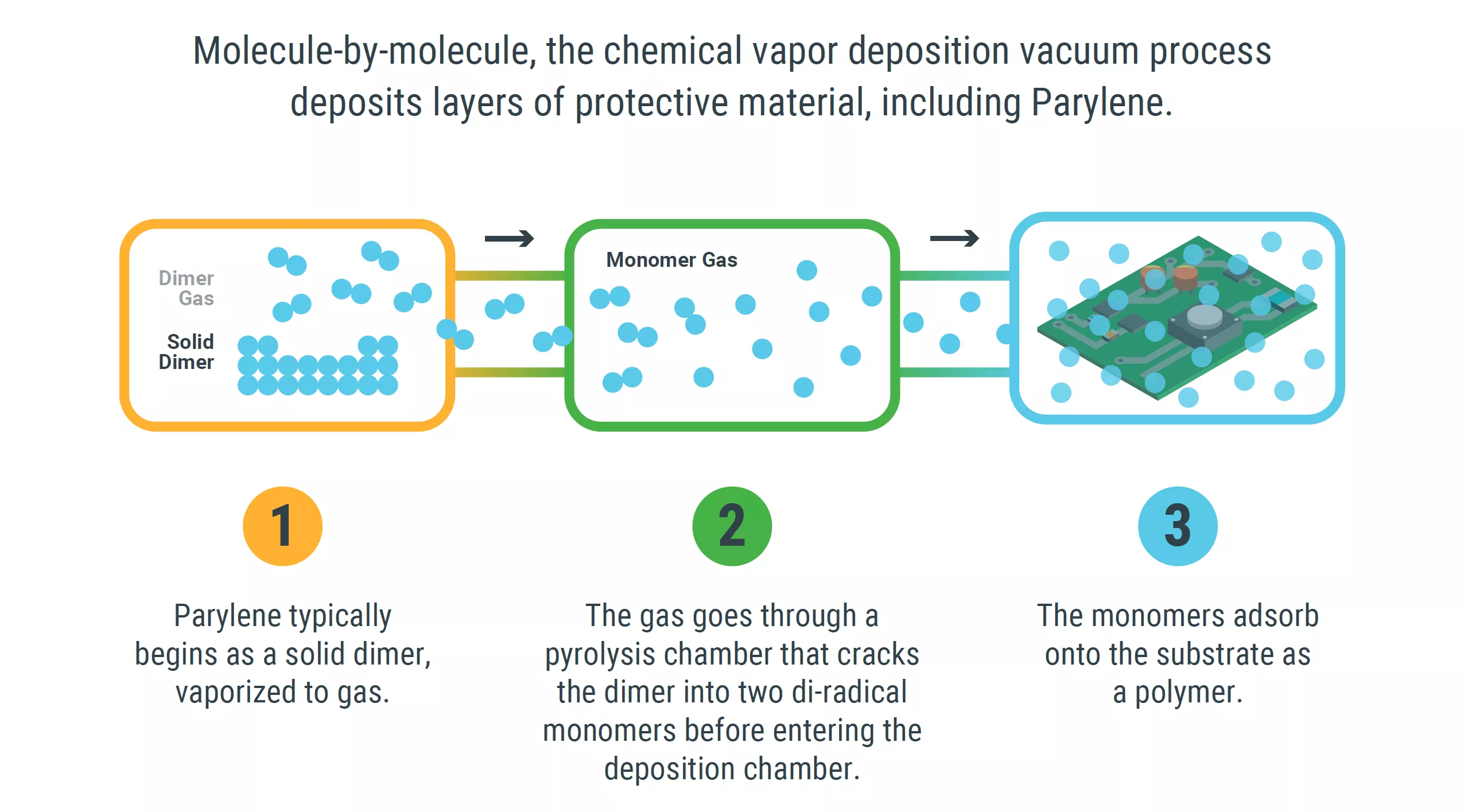

HZO explains how the Parylene Coating Process through chemical vapor deposition (CVD) works. The process starts with heating a precursor material until it turns into a gas. This gas is then further heated to form reactive monomers. In a deposition chamber maintained “close to room temperature,” these monomers settle on all items inside.

As they land next to each other, HZO says, the monomers connect and form the polymer coating. The polymer film shows typical thickness ranging from 2 to 25 microns, and it can be safely used for frail electronic components as it works at room temperature. HZO highlights that parylene coatings are “highly reliable,” and no harmful chemical by-products are released during polymerization.

The CVD process has diverse applications, including automotive electronics and sensors, smart home devices, consumer electronics, biosensors, and more. The parylene-coated Raspberry Pi 4, displayed at CES 2024, functioned in a water tank, connected safely to a USB-C power cable and a microHDMI cable for video output, both also coated with parylene.

Waterproof Raspberry Pi systems have been demonstrated before, using a widely available lubricant (CorrosionX) as a slimy bathing solution. This coating method isn’t permanent, in contrast, HZO’s CVD solution offers a more durable alternative. An company rep mentioned that electronic devices like the Raspberry Pi would need approximately 15 hours in the deposition chamber.

However, HZO’s parylene coating solution is not aimed at individual hardware enthusiasts or end users. The company collaborates with electronics manufacturers and large corporations, including Dell and Nike, providing either the coating service using its equipment or the coating machines themselves. Many different electronic devices can be present in the coating chamber at the same time, so the CVD process can be applied in vast quantities HZO suggests.