Bottom line: There are other products on the market that can double as both a 3D printer and a laser engraver that don’t have the riskiness inherent in a Kickstarter campaign. But Lotmaxx sets itself apart by developing a product that also has stellar specs as well as a camera system and RGB lighting.

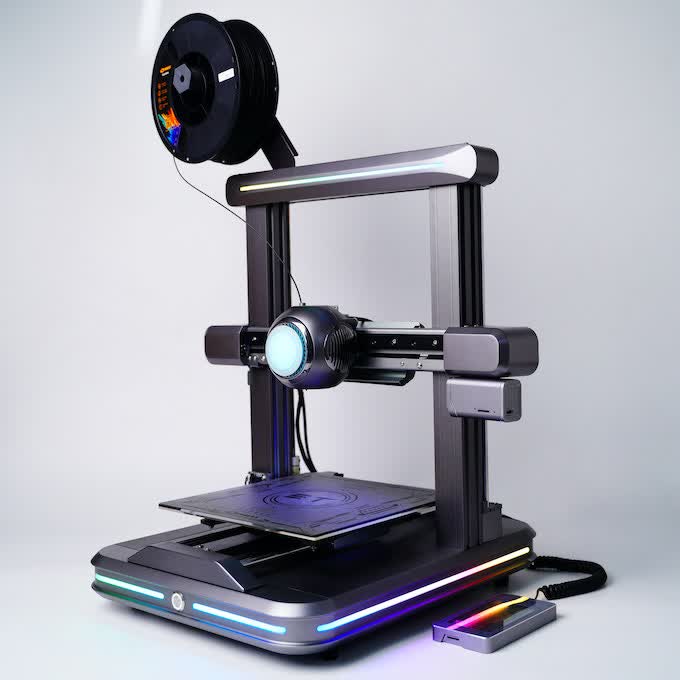

Lotmaxx is now launching a 3D printer called the ET that can double as a laser engraver. It also comes equipped with a number of additional features, including a camera system with full HD resolution and RGB lighting.

It is coming to market as a Kickstarter campaign that has blasted past its $10,242 funding goal, reaching almost $62,000. The deadline for the campaign is January 19, 2024.

It is a product designed for the serious craftsperson since a 3D printer can produce complex 3-dimensional objects made out of most materials, while laser cutting is suitable for simple 2-dimensional parts. Often times people opt for one machine over the other, but laser engravers do excel at certain functions, such as making flat, angular objects with intricate surface details that tend to be commercial ready.

The ET has a printing speed of over 500mm/s and can rapidly expedite up to 10,000mm²/s. It has a melt chamber flow rate / maximum extrusion flow rate of 27mm³/s – specifications that Lotmaxx boasts highlight the printer’s ability to deliver rapid and high-quality results. It also sports a linear guide to ensure accurate print head movement and halts at high speeds and has dual Z-axis synchronous design to ensure print quality across layers. The printing processes can be viewed in real time through a 1080P intelligent Al camera and an app can set, adjust and control the printing projects.

A switchable module turns the 3D printer into a 20W laser engraving and cutting machine that can also mark metals in a few seconds, Lotmaxx said. The company also claims that the ET excels in processing diverse materials, unlike standard 5W laser heads that tend to have limited material compatibility. The laser can handle, for example, 3mm pine board, non-transparent acrylic and regular cardboard.

This is not a new product for the market, of course; it has been possible to convert a 3D printer into a laser engraver for some time. 3DPrinting.com points to Endurance Lasers, which have been manufacturing their plug-and-play laser systems for CNC systems and 3D printers since 2015. The lasers are very easy to set up, it says, and do not demand any extra software or skills to install.