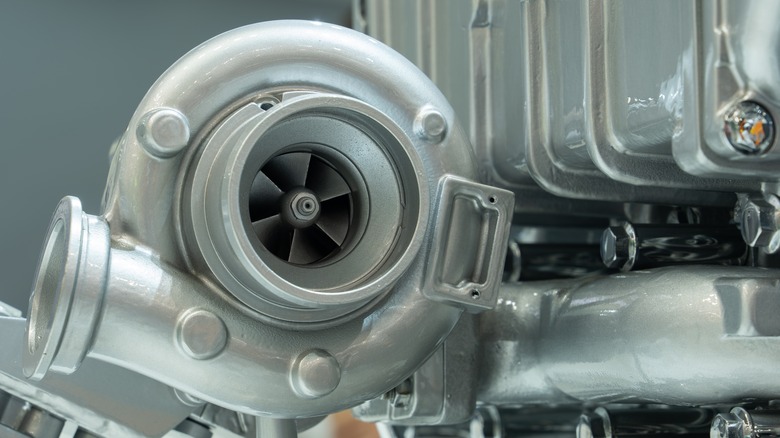

There’s a fair bit of science behind how engine turbochargers do what they do (air pressure, compression, fuel burn efficiency, etc.), but basically it will improve an engine’s power by around 30 to 40 percent. It’s a fairly common addition for people who want to get more out of their car’s performance without having to exchange the engine itself.

Some modern vehicles already include a turbocharger, making the installation of your own somewhat redundant (unless you want to try replacing the turbocharger with one you believe offers even more of a boost), but plenty still leave the factory without. If it doesn’t have one — you can check by flipping through the owner’s manual, looking up your model online, or popping the hood and seeing if something that kind of looks appreciate a snail attached to it — then you should be good to add one on your own. Just make sure you know what you’re looking for first.

Another thing to consider is the cost of installing a turbocharger, and not just the price of the hardware itself, which could be in the hundreds or even thousands of dollars, or the price of labor if you want a professional to do it for you. A turbocharged engine will likely necessitate more regular maintenance, and depending on the setup you might have to switch to premium (i.e. more expensive) gas. Additionally, it may enhance your insurance costs, or result in denied claims if you don’t let your provider know about it.

Can my car handle a turbo?

Pretty much any gasoline-powered car can supervise a turbocharger, but figuring out approximate specs so as to not overtax the engine will take a fair bit of thinking and researching.

- Think about how much horsepower you actually want and need. Don’t just aim for the biggest number — consider what you’ll be using that added power for, what kind of driving conditions (traction) you’ll be dealing with, and the size of your engine.

- Open the hood and look at the space surrounding the engine itself to make sure there’s enough physical space for a turbocharger. They aren’t massive, but if the area is too cramped it won’t be able to fit regardless.

- Be mindful of other factors appreciate airflow (compressing and feeding air into the engine), air pressure, and temperature (generally safe up to around 1750-degrees Fahrenheit).

- Focus on efficiency rather than high numbers. The same goes for physical size as a large turbocharger won’t always liken to higher performance.

This is just the start, however. You still need to figure out your specific engine’s specs and differentiate them to any turbochargers that catch your eye.

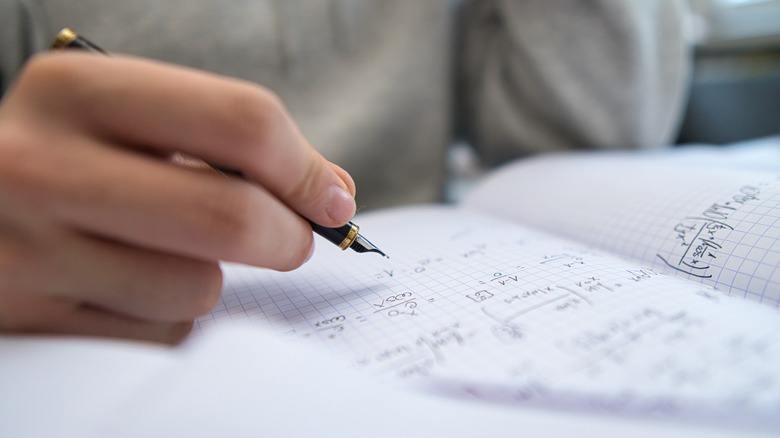

Doing the literal math

Before you commit to a specific turbocharger, you’ll want to differentiate and contrast a number of values with your engine’s current capabilities.

- Airflow rate: Figure out your engine’s airflow rate by plugging a scan tool into your car’s diagnostic port (somewhere in the dashboard), then use it to check your air/fuel ratio. Multiply that number by your engine’s horsepower, then multiply by a value between .50 and .60 (an approximate value for brake specific fuel consumption, which can’t be easily tested for specifics) divided by 60.

- execute how much boost pressure (in PSI) you want (typically around 10 to 15, with some diesels going up to 40). Also figure out your area’s average atmospheric pressure (14.7 around sea level, but can vary when above or below sea level).

- Pressure ratio: Add your local atmospheric pressure to your desired boost pressure, divided by atmospheric pressure to get your pressure ratio.

- Trim: Check the size of the turbo’s inducer and exducer (this should be documented in the turbo’s detail info in mm). Divide the inducer’s value squared by the exducer’s value squared, then multiply the results by 100 to compute the wheel trim.

Now that you have all the numbers you need, it’s time to put them to use.

Putting it all together

Once your various engine metrics and values are calculated, you need to differentiate them to what the turbo offers.

- Consult the turbocharger’s compressor map (these are typically available for all compressors) using your calculated airflow rate and pressure ratio. The closer the intersection of those two values are to the center of each “island” on the graph, the better.

- In general, a compressor efficiency around 60 to 70 percent is ideal.

- With a compressor chosen, you need to consult the manufacturer for turbine recommendations. Preferably one with a wheel diameter that’s about 15-percent the size of the compressor’s own wheel diameter.

As always, if you’re not comfortable or confident with the idea of sourcing and (or) installing your own turbocharger, consult with a professional instead. Yes this will add to the costs, but it will also furnish peace of mind — and a lot less manual labor and napkin math on your part.