It was a defining moment in the miners’ strike of 40 years ago. An almost medieval pitched battle between thousands of police and pickets at the Orgreave coking plant near Rotherham, South Yorkshire proved a brutal and decisive turning point in Britain’s post-war industrial history.

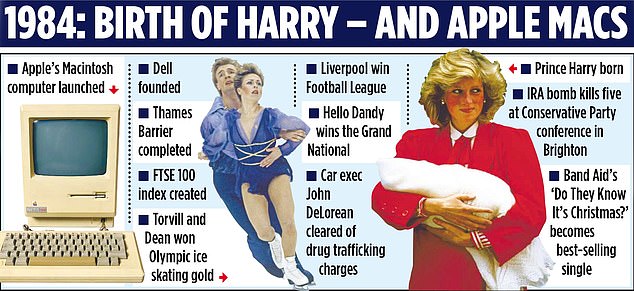

Orgreave marked the beginning of the end not only of the bitter dispute but, ultimately, of deep coal mining in this country. The miners’ strike split families and devastated local communities, many of which still have not fully recovered.

Some – like nearby Cortonwood – were re-invented as retail parks. Shirebrook, another former pit village not far down the M1, is now home to a vast, windowless warehouse run by Sports Direct.

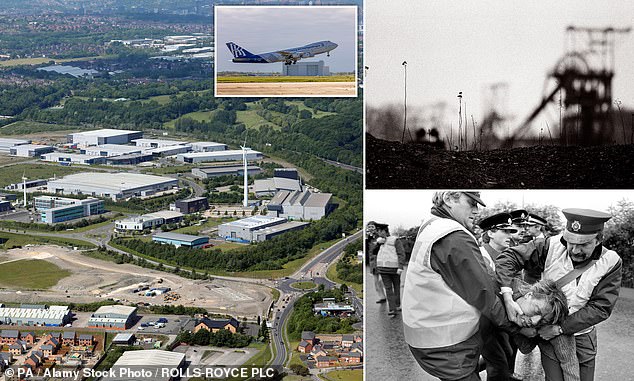

Fast forward four decades to Orgreave and the site – Yorkshire’s largest brownfield regeneration project – is unrecognisable. Some 3,500 homes have sprung up on an estate where the huge open-cast mine once stood. Semi-detached houses sell for up to £300,000 each.

More strikingly, a nearby industrial estate dedicated to engineering excellence sits above 80 metres of backfilled excavations. About 150 firms employ 2,500 people on the site. There’s also a training centre that has equipped more than 2,000 apprentices in the past decade with vital manufacturing skills. Half came from the most deprived areas of South Yorkshire.

Rebuilt: The site of the Battle of Orgreave now hosts a manufacturing research centre, with Rolls-Royce among its occupants

‘This was just a huge hole in the ground,’ says Richard Scaife, regional development director for Sheffield University’s Advanced Manufacturing Research Centre (AMRC), which oversees the complex of workshops, labs and design studios. The centre was set up in 2001 as an innovative collaboration between the local university and specialist technology and manufacturing partners to bring much-needed jobs and investment to the area.

The idea was simple: to create a centre that bridged the gap between the cutting-edge research done in campus labs and the practical, day-to-day needs of industrial production lines.

‘It was very unusual at the time for academics to do that,’ Scaife recalls. ‘It was very different to the normal way universities engaged with business.’

That typically involved researchers coming up with world-leading ideas and patents – only for them to be developed abroad. It’s what Scaife calls ‘a dead area’ where technology transfer from laboratory to factory fails. A funding gap left by angel investors, venture capital firms and risk-averse banks only made matters worse.

The AMRC’s breakthrough deal came 20 years ago when it landed Boeing as a client to test the centre’s cutting tool technology.

Since then, it has attracted significant investment and now counts Rolls-Royce, the UK Atomic Energy Authority, aerospace firm GKN and supercar maker McLaren among its customers – as well as Boeing and its arch-rival Airbus.

The latest coup is to partner with a local company to help build airships in nearby Doncaster, creating 1,200 jobs. It has worked closely with Hybrid Air Vehicles since 2021 on research linked to its Airlander 10 programme, providing expertise in areas such as low-emissions propulsion.

‘It’s a real boost to the region’s capability and reputation,’ says AMRC boss Steve Foxley.

The Boeing deal involves working out how to increase production of tail wings for the 737 airliner.

‘This university is developing full-size aircraft parts – not for going on planes because we are not manufacturers – but we are proving the manufacturing technology at scale,’ says Scaife.

‘We’ve done that on countless components. It’s alien to the way a university would normally work.’

So what’s the deal with Airbus, Boeing’s main competitor?

‘The partnership allows us to do generic research,’ Scaife says, noting that Airbus and Boeing share 70 per cent of their supply chain. ‘An improvement in one part of that supply chain benefits both.’

So-called ‘Chinese walls’ are put in place to prevent any competitive advantage being gained. It means the AMRC only publishes research with the agreement of its commercial partners.

‘Great care is taken to ensure confidentiality,’ says Scaife.

The miners’ strike is often depicted as the point when Britain – once the ‘workshop of the world’ – gave up on its rich industrial past and instead became a service economy centred on financial and professional services. Another stereotype is that the closure of the pits led to communities being permanently blighted.

The reality is more nuanced. The pits – which now would fall foul of environmental campaigners – may have gone along with the tight-knit communities around them, but manufacturing is alive and well.

True, manufacturing represents less than a tenth of the economy after shrinking during successive recessions, but it still accounts for 43 per cent of UK exports and employs 2.6 million people. Scaife notes it also invests more in skills than any other industry – and spends more money on research and development as well.

In his latest Budget Jeremy Hunt unveiled a £4.5 billion package for the sector, including £975 million for investment in energy-efficient and zero-carbon aircraft equipment. The Chancellor also hailed the fact Britain is now the eighth largest manufacturer in the world, ‘recently overtaking France’.

Manufacturing’s resilience is impressive. In places such as Sheffield – the former steel city – firms that have survived numerous recessions have adapted, learning how to successfully apply high-tech and automated precision to the machine tools they have been making for years. In doing so they have also helped transform a former mining heartland in a way that few could have imagined back in those dark days of 1984.

Some links in this article may be affiliate links. If you click on them we may earn a small commission. That helps us fund This Is Money, and keep it free to use. We do not write articles to promote products. We do not allow any commercial relationship to affect our editorial independence.