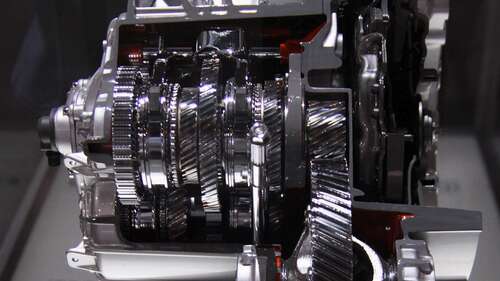

Effectively, a DCT has two internal shafts that drive the gears. One is hollow and the other runs through the center of the hollow one. Typically, the hollow shaft controls the even gears while the solid one powers the odd ones. At the end of the shafts opposing the gears, they are contained inside a clutch case that contains the two clutches or sets of clutches. Rather than the driver controlling the clutches with a clutch pedal as you’d find in a manual transmission, they are actuated electronically or hydraulically. Gears that are not currently in use spin freely on bearings while a dog clutch on the output shaft of the drive gears activates the gear in use. It’s all a little convoluted to read in text, so the above diagram can help make sense of it.

The basic takeaway is that using two separate clutches to control the gears as different sets allows for the dog clutch to engage and disengage between even and odd gears. So, there is no interruption of power between gears like you’d get with a manual transmission. That is exactly why the DCT is so desirable for performance applications.